LPG Orange Band LPG Orange Band

Type: Rubber - LPG Hose 'Orange Band' Liquid Petroleum Gas hose to EN 1762. For propane, butane and their mixtures to...

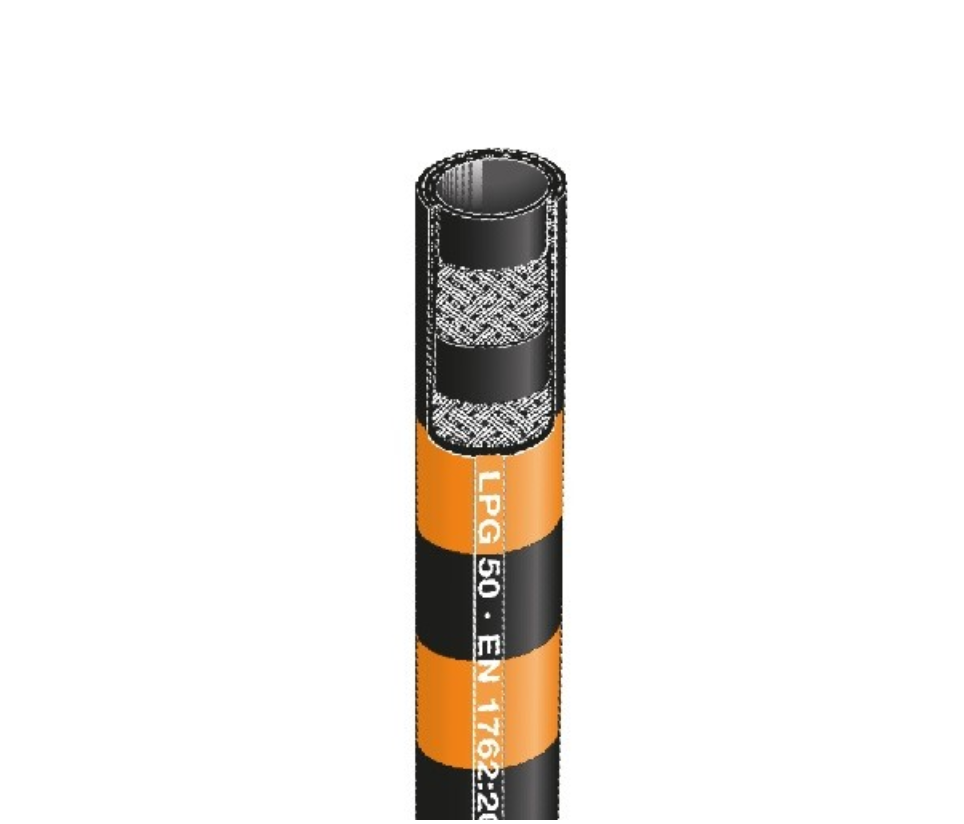

Type: Rubber - LPG Hose

'Orange Band' Liquid Petroleum Gas hose to EN 1762. For propane, butane and their mixtures to EN 589. As the hose lining is resistant to diff usion the hose is also suitable for natural gas. Not suitable for ammonia. Rugged and long-lasting construction with low tensile braids.

Permitted working pressure: 25 bar,

Burst pressure: > 100 bar.

Temperature range: - 40° C up to + 70° C ( Special type LPG-LT does not crack down to - 50° C ).

Approved by DVGW, approval No. DG-4621 AU 0049.

Application: As reel hose for supplies to domestic and industrial storage tanks, as pump hose for vehicle refuelling, for bulk loading and unloading from rail tankers, road tankers and ships. For special suction / pressure operation needs the type LPGS with stainless steel helix is available on request. * )

Please Note: marking of LPG 10 ( BUTAPAL 10 ) with longitudinal orange stripe.

Marking: orange bands every 2,5 mtr.. Continuous, abrasion resistant embossing as specifi ed in the EN standard 1762

Lining: Nitrile rubber ( NBR ), black, electrically conductive, diff usion resistant

Reinforcements: Textile braids with 2 crossed tinned copper strands

Cover: Chloroprene ( CR ), black, electr. conductive, flame and abrasion resistant, ozone, UV and ageing resistant

| Part Number | Name |

Inner Diameter (mm) |

Outer Diameter (mm) |

Working pressure (bar) |

Test pressure (bar) |

Vacuum (bar) |

Bend Radius (mm) |

Coil Length (m) |

| 10 5210 | Hose LPG Band 10mm | 10 | 20 | 25 | 40 | 0.8 | 70 | 40 |

| 10 5213 | Hose LPG Band 13mm | 13 | 23 | 25 | 40 | 0.5 | 80 | 40 |

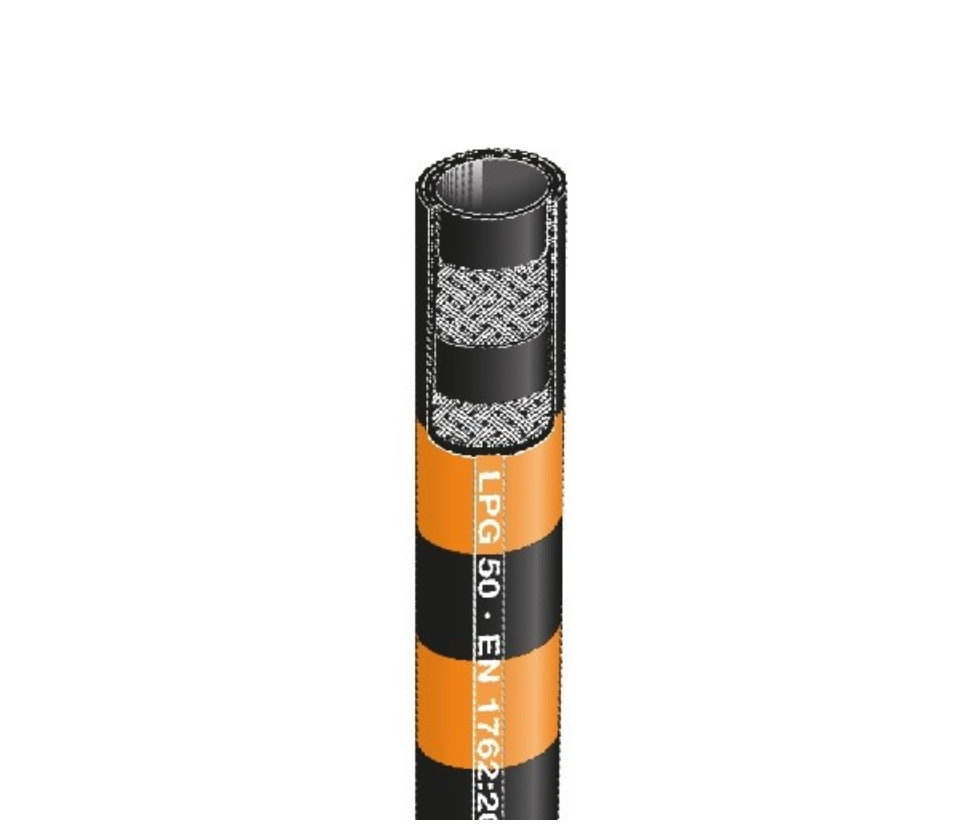

Type: Rubber - LPG Hose

'Orange Band' Liquid Petroleum Gas hose to EN 1762. For propane, butane and their mixtures to EN 589. As the hose lining is resistant to diff usion the hose is also suitable for natural gas. Not suitable for ammonia. Rugged and long-lasting construction with low tensile braids.

Permitted working pressure: 25 bar,

Burst pressure: > 100 bar.

Temperature range: - 40° C up to + 70° C ( Special type LPG-LT does not crack down to - 50° C ).

Approved by DVGW, approval No. DG-4621 AU 0049.

Application: As reel hose for supplies to domestic and industrial storage tanks, as pump hose for vehicle refuelling, for bulk loading and unloading from rail tankers, road tankers and ships. For special suction / pressure operation needs the type LPGS with stainless steel helix is available on request. * )

Please Note: marking of LPG 10 ( BUTAPAL 10 ) with longitudinal orange stripe.

Marking: orange bands every 2,5 mtr.. Continuous, abrasion resistant embossing as specifi ed in the EN standard 1762

Lining: Nitrile rubber ( NBR ), black, electrically conductive, diff usion resistant

Reinforcements: Textile braids with 2 crossed tinned copper strands

Cover: Chloroprene ( CR ), black, electr. conductive, flame and abrasion resistant, ozone, UV and ageing resistant

| Part Number | Name |

Inner Diameter (mm) |

Outer Diameter (mm) |

Working pressure (bar) |

Test pressure (bar) |

Vacuum (bar) |

Bend Radius (mm) |

Coil Length (m) |

| 10 5210 | Hose LPG Band 10mm | 10 | 20 | 25 | 40 | 0.8 | 70 | 40 |

| 10 5213 | Hose LPG Band 13mm | 13 | 23 | 25 | 40 | 0.5 | 80 | 40 |